Software & Controls

Latest News

Advertisement

Advertisement

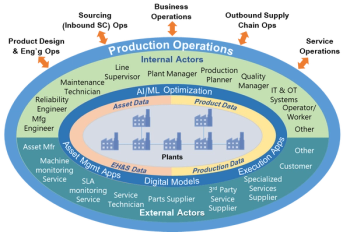

The benefits of a digitalized, software-driven world for turbomachinery include the capacity to handle large amounts of data. Now, engineering teams can run larger, more complex simulations using cloud services and pass data seamlessly between teams.

A simulated product model can visualize exactly when and where maintenance is needed, instead of making blind guesses and safe bets.

State-of-the-art tools for turbomachinery advance and simplify engine design, field service, training and maintenance.

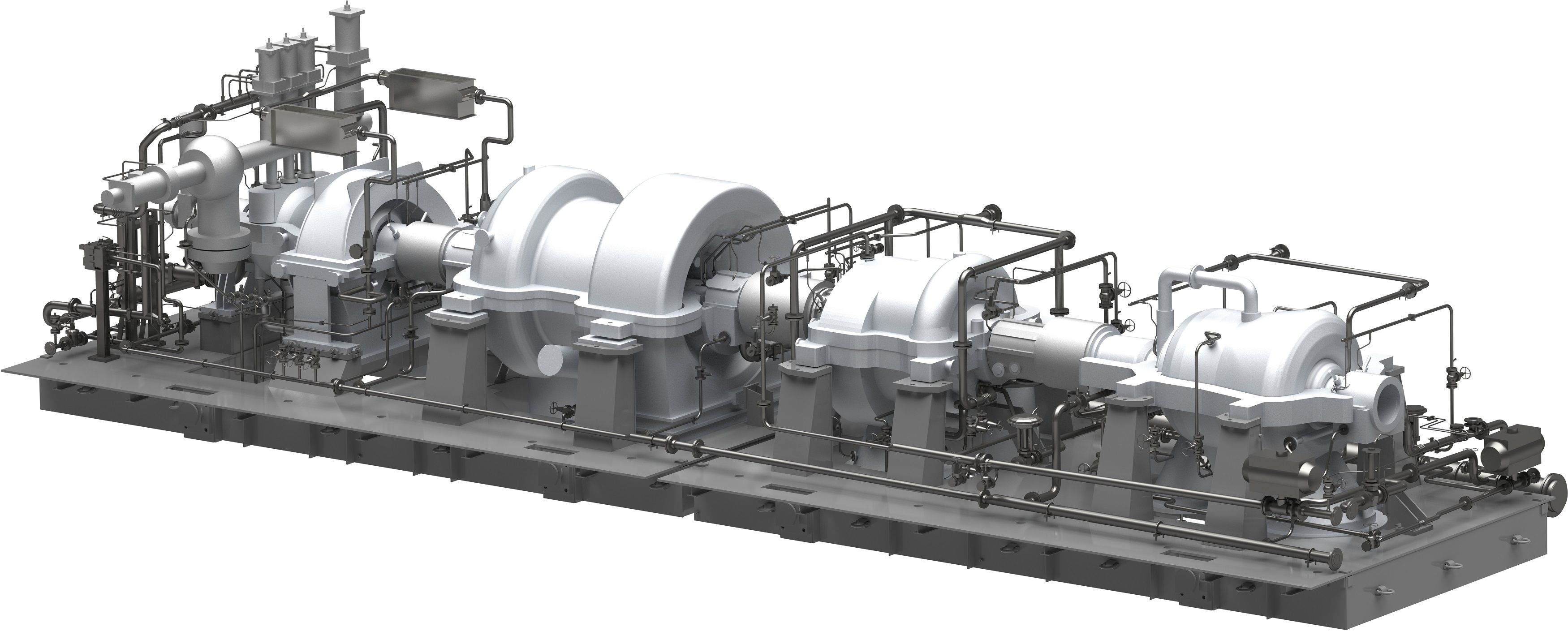

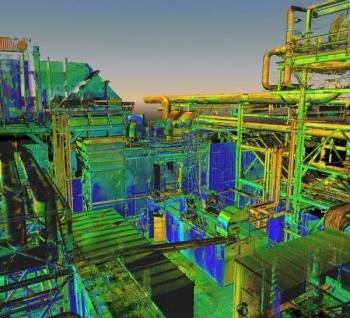

As-built models created by laser scanning are accurate to an eighth of an inch. All the detail around the turbine and compressor can be captured rapidly by correct placement of laser scanners.

Advertisement

Advertisement

Trending on Turbomachinery Magazine

1

Benoit Outlines PSM-Baker Hughes Collaboration for Ammonia-Based Maritime Transport

2

Scaling U.S. Manufacturing for Advanced Compressor & Turboexpander Demand

3

Turbomachinery News Network: SoftInWay, Mitsubishi Power, Siemens Energy, and more

4

Capstone Green Energy’s C1000S Microturbine to Power Compression Station in Brazil

5