ABB’s Genix Datalyzer is a cloud-based data analytics solution for fleet-wide management and optimization of emissions monitoring equipment.

ABB’s Genix Datalyzer is a cloud-based data analytics solution for fleet-wide management and optimization of emissions monitoring equipment.

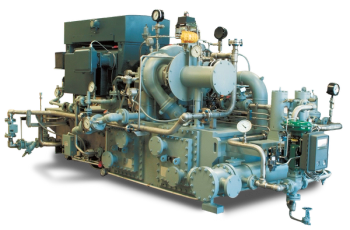

Oil-free air and gas compressors.

The system is compliant to API 670 and meets IEC 61508 up to SIL-3 standards.

The ROC provides IPSC clients truly remote operation, monitoring and start/stop control of existing simple cycle gas turbine peaking projects.

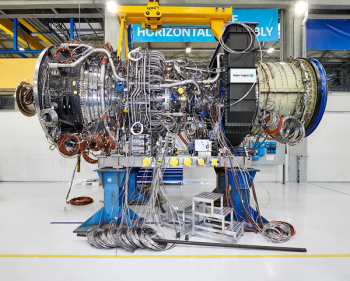

Lowering carbon emissions from gas turbines.

Companies are increasing their investment in the industrial internet of things, AI, and cloud technology.

Some of NATEV GmbH's products include hardware and software used to monitor production steps linked to the tightening process.

Dan Phillips, Technical Director, Monitoring and Diagnostics, Regal, discusses couplings, the Internet of Things, remote monitoring, diagnostics, and smarter maintenance practices.

GE made upgrades to the plant's gas turbine, steam turbine, and software.

NATEV GmbH will be integrated into Atlas Copco's Assembly Systems Division.

Show highlights the many aspects of LM Series operations and maintenance.

The RMC will provide continuous monitoring across a variety of oil and gas assets.

Mitsubishi Power Americas and the University of Central Florida have formed an industry-education partnership to establish a NOx emission tracker.

Vortex Manufacturing recently purchased a second additive manufacturing solution from Velo3D.

The technology uses AI to support plant operation and maintenance planning.

Controls vendors are coming to market with advanced features anchored by enhanced cybersecurity.

The companies will merge on October 1st.

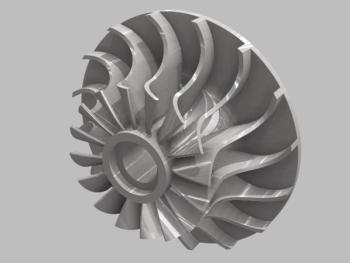

The software provides students with 3D renders of compressors and turbines.

Nexus Controls provided consultation and technical support for an Egyptian LNG plant

B&K Vibro announced the newest versions of its VCM-3 along with its Setpoint CMS solution

Texas A&M University students collaborated with Siemens Energy to deliver a rotating equipment selector app to aid in product selection.

Garland Technology and Dragos announced a partnership that will enhance cybersecurity for industrial controls systems and industrial environments

The company has been awarded a Phase II contract to expand its work developing an axial compressor map generation program

The German company is partnering to deploy artificial intelligence (AI) to aid decision-making in nitric acid plant operation.

As 3D printing grows in sophistication and maturity, more companies are incorporating it.