Software & Controls

Latest News

Latest Videos

Shorts

Podcasts

More News

In addition to delivering centrifugal compressors and LM9000 aeroderivative gas turbines, the full scope includes commissioning services, spares and warranties, and full string tests.

The wet gas scrubbing system features high SO2-removal efficiency, low-pressure operation, reduced energy consumption, and accommodates site layouts with customizable designs.

The client, a frozen food manufacturer, will integrate the C800S microturbine to significantly reduce energy costs, lower pollutant emissions, and improve operational reliability.

In addition to electrical submersible pumps, the FusionPro and Leucipa solutions will enhance operational reliability and minimize non-productive time for Kuwait Oil’s fields.

The C1000S microturbine system will generate combined heat and power to support the manufacturing facility’s growing energy demands for oat processing.

Previously, the undisclosed operator shifted its strategy from equipment availability to long-term reliability and enlisted John Crane to solve sealing inconsistency issues at a flagship refinery.

In comparison to traditional supercomputers, quantum computing offers a notable speed advantage and may accelerate simulation time exponentially.

The precision and efficiency of laser-based welding systems can address key industry challenges, such as labor shortages, operational downtime, and quality consistency.

Combining Overwatch’s SIDE Platform with Idemitsu’s natural gas supply will help meet rising demand from hyperscalers, GPU-cloud providers, and investors seeking to build AI computing.

The November/December 2025 issue covers steam turbine blade dynamics and aerodynamics, gas turbine bucket repair, a TPS 2025 recap, a Q&A with Ebara Elliott Energy, and much more.

On the power generation side, Caterpillar and Solar Turbines will supply natural gas turbines and reciprocating engines to provide data centers with electric power and thermal energy.

Separate from liquid ammonia operation, the ME-LGIA also sends real-time engine and operational data to Everllence shore-based monitoring to improve performance.

Kozienice is transitioning away from coal-fired power generation, instead using natural gas to generate up to 60% less emissions compared to fossil-fired plants of a similar size.

In 2024, the Industrial Process manufacturing facility secured $160 million in orders and is targeting over $300 million in annual orders by 2030.

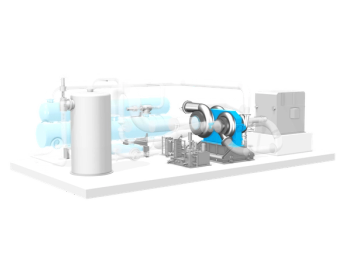

The magnetic bearing technology reinforces an oil-free design, eliminating the need for a lubrication oil system and preventing wear on sliding parts.

Performance Plus combines data-driven monitoring, expert consultancy, and hands-on training to help turbomachinery users reduce downtime and boost reliability and long-term resilience.

The mtu Series 4000 DS 3600 diesel generators will operate reliably under extreme climatic conditions, designed for ambient temperatures up to 55 °C.

With Antea’s mechanical integrity capabilities, Cordant will link inspection data to asset strategy and performance to optimize maintenance and reduce OPEX costs.

Under the additional contract for Train 5, Baker Hughes will deliver two Frame-7 gas turbines and six centrifugal compressors to support approximately 6 MTPA at the facility.

In addition to installing the world’s largest steam heat pump at Kendall Station, Everllence will include a dynamic process simulation and digital twin of the system.

MARA Holdings will construct numerous power generation facilities and data centers near MPLX’s natural gas processing plants across the Delaware Basin.

The new update improves volute modeling with enhanced 3D models and tongue geometries, in addition to expanded leakage path capabilities with a secondary network solver.

Under the pilot project, the partners will develop ammonia cracking systems to build out hydrogen and ammonia supply chains and decarbonization technologies.

Since installation, the Fadhili Gas Plant has demonstrated a 10 – 15% reduction in amine and steam usage and an approximately 5% reduction in power usage.

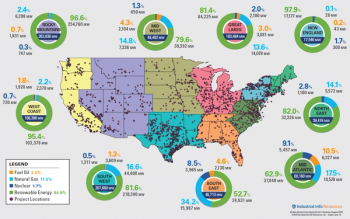

Roiled by executive orders, agency rulemakings, and other initiatives, the U.S. power generation landscape has shifted dramatically this year from renewables to dispatchable generation. What’s more, vast and ever-rising estimates of electric demand growth created by data centers, artificial intelligence, and advanced manufacturing are adding to the turbulence.