This year’s Turbo Tour schedule took us around the country and over the pond, with insights on GE Vernova, EthosEnergy, Mechanical Solutions, and SSS Gears.

This year’s Turbo Tour schedule took us around the country and over the pond, with insights on GE Vernova, EthosEnergy, Mechanical Solutions, and SSS Gears.

The top 10 articles of 2024 include cover stories on the LNG industry and digital twins, Myth Busters and Turbo Tips columns, a gas turbine sales report, and much more.

A collection of thought leaders, turbomachinery experts, and government representatives gathered throughout 2024 at major conferences: POWERGEN, WTUI, Turbo Expo, and TPS.

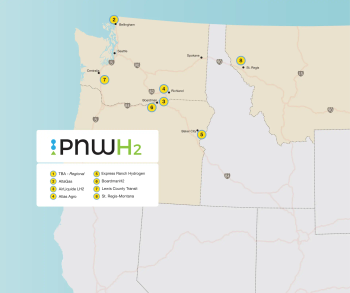

Node 6 will produce hydrogen via electrolysis and peak-power generation with 100% hydrogen-capable turbines.

The heat-pump system uses Rhine water as its energy source and operates with a natural refrigerant in a closed-loop system.

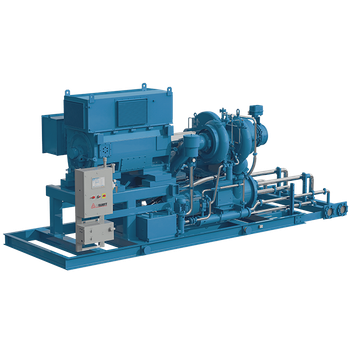

The P650 features a removable air-end design and horizontally split air-end components to allow for undisturbed inspection and maintenance.

The letter increases the planned data center’s capacity from 90 to 250 MW to support heightened electricity demand; New Era Helium will supply gas at a fixed price for five years.

Advanced compressor technologies, AI and ML, and cooling technologies help reduce energy usage, carbon emissions, and at times, cost.

Following two years of design collaboration with the U.S. Air Force and Boeing, the F130 aircraft engine will soon enter production for the B-52J Stratofortress.

The 138-Kv breaker and numerous capacitor banks will regulate voltage dips and swells to protect customer and company equipment during tests up to 100 MW.

Curtiss-Wright and Sintavia’s additively manufactured metal impeller design was installed in the submarine pump system of a Navy vessel and tested at a facility in Bethlehem, PA.

EthosEnergy’s turbine workshop and Performance Center work hand-in-hand to maintain operators’ turbine equipment and provide remote operations and monitoring.

The planned 515-MW power plant project will increase Ghana’s thermal generation capacity by over 7%.

The storage system uses the ETI-Z25.HP heat pump-type centrifugal chiller that will use groundwater to cool the Japanese plant.

The high-precision, non-contact displacement sensors complement condition monitoring systems by measuring and monitoring runout, speed, and changes in machine vibration profiles.

GridOS orchestration software will help Tensio AS and Linea AS manage energy demands with increased visibility, accelerated decision-making, and built-in security.

The November/December 2024 issue highlights emerging decarbonization efforts that integrate hydrogen, ammonia, and new technologies into increasingly intermittent grids.

DOE awarded GE Aerospace, Boeing, and NASA supercomputer access to study open-fan aerodynamics to reduce drag and improve fuel efficiency.

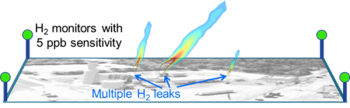

The project will deploy a high-fidelity gas sensing technology that uses dielectric excitation and physics-enhanced analytics to detect hydrogen leaks at industrial locations.

Part two of this myth on centrifugal compressor maps delves into the map’s extrema: surge and choke.

Baker Hughes’ systems will reduce CO2 and recover the flare gas equivalent of up to 7 million Nm3 of methane per year and then be used as fuel within the Baku Oil Refinery.

GE Aerospace’s lean operating model and overall industry growth have spurred investments by standardizing processes and fostering operational efficiency and reliability.

United Aerospace Maintenance Co. will fulfill the customers’ CFM LEAP maintenance needs in Europe, the Middle East, and Africa by conducting on-wing-support and near-wing retrofits.

Kawasaki and Low Emission Technology Australia will reduce emissions from the heavy industry by capturing CO2 at the source.

The AI-assisted borescope inspection technology raised model recall rates by 33.6% and increased model precision rates by 13.5% compared to the previous Gas Power-assist model.