EthosEnergy’s contract with Energia 2000 supports the Dominican Republic-based 420-MW combined-cycle facility set to open later this year.

EthosEnergy’s contract with Energia 2000 supports the Dominican Republic-based 420-MW combined-cycle facility set to open later this year.

The microturbines will operate in a combined heat-and-power configuration, generating electricity for a wastewater treatment facility in Wisconsin.

The Kansai Mitsubishi CO2-recovery process extracts carbon from flue gas at the Himeji plant, and the ΣSynX Supervision remote monitoring system collects pilot data.

The Turbomachinery News Network, for the week of May 5, 2025, covers news from GE Vernova Hitachi/GE Vernova, Ansaldo Energia, EthosEnergy, and Baker Hughes.

The Flame Tracker Increased Low Gain is more sensitive to low-light environments, allowing it to quickly identify flames and trigger shutdown to prevent damage or explosion.

President Trump and the Prime Minister of Saudi Arabia’s visit prompted the collaboration with GE Vernova to potentially supply advanced heavy-duty gas turbines built in Greenville, SC.

EthosEnergy will conduct routine inspections and preventive maintenance at the 850-MW facility that houses Siemens Energy’s turbines and gensets.

Drake Controls has locations in the United States and Mexico, allowing Score to grow its intelligent control platform for turbines, compressors, and more.

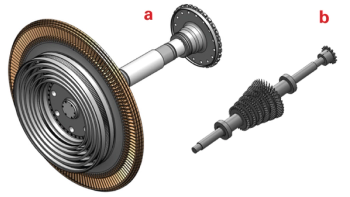

Exergy International developed a high-speed axial turbine for waste heat recovery in organic Rankine cycle power plants.

The UAE-based 1-GW plant, connected to a nearby large-scale photovoltaic park, includes Ansaldo Energia’s 24/7 monitoring and technical support.

Fusion Inc. joins RMS’s domestic repair network, offering customers thermal spray coatings, laser cladding, and other critical turbomachinery services.

The May/June 2025 issue spotlights the gas turbine market, deep-diving into order activity, the impact of surging power demand, and how the industry is responding.

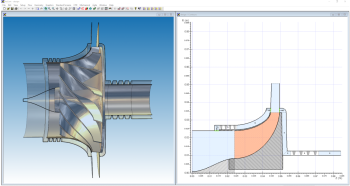

How accurate are advanced computational tools like CFD and FEA? Find out in part II of designing turbomachines with the Myth Busters.

Duke Energy is installing 11 of GE Vernova's 7HA turbines across numerous power projects using current infrastructure and transmission capabilities to satisfy AI-driven demand.

The Turbomachinery News Network, for the week of April 21, 2025, covers news from Capstone Green Energy, bp, Chevron U.S.A., and TMC Compressors.

Nikon’s research program at the University of Waterloo will combine direct energy deposition and titanium powders to repair damaged or worn aerospace components.

Do engineers overrely on computational tools? The Myth Busters deep dive into engineering tools, such as CFD and FEA, used to design turbomachines.

The compressed air systems, which include controls, service air compressors, and ease-of-maintenance features, will be installed on 12 under-construction LNG carriers.

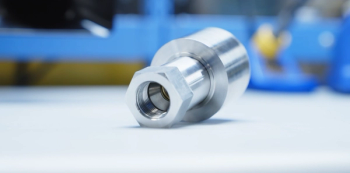

Renovating modern dry gas seals and their systems increases reliability.

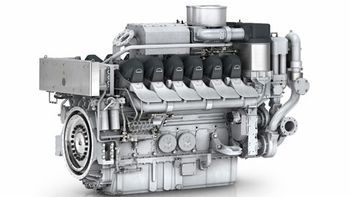

Dietmar Zutt of MAN Energy Solutions says the latest combustion and control technologies allow the 175D to achieve rapid maneuverability, acceleration, and long cruising ranges.

In addition to a second C65 microturbine, the plant will use a Vergent remote monitoring controller to track the combined heat-and-power system.

Asma Abaalkhail of GE Vernova says its Live Outage system and all-Saudi team completed the gas turbine outage operation safely and days ahead of schedule.

Centrifugal compressor manufacturers are incorporating magnetic bearings, variable-speed drivers, digital twins, and more to improve performance and reliability.

The Turbomachinery News Network, for the week of April 7, 2025, covers news from Baker Hughes, Concepts NREC, GE Aerospace/MTU, Shell, and Mitsubishi Heavy Industries.

The update also includes a new computational fluid dynamics code powered by a graphics processing unit, running 15 - 120x quicker than current rotating machinery solvers.