Per Dora Partners’ Christean Kapp, the Chinese compressor market is acquiring foreign technologies, making improvements, and beginning exports to the Middle East and Asia.

Per Dora Partners’ Christean Kapp, the Chinese compressor market is acquiring foreign technologies, making improvements, and beginning exports to the Middle East and Asia.

With Antea’s mechanical integrity capabilities, Cordant will link inspection data to asset strategy and performance to optimize maintenance and reduce OPEX costs.

The company will service and maintain multiple units at the Taishan nuclear power plant, in addition to supplying a steam turbine, generator, and controls for the Natrium Wyoming plant.

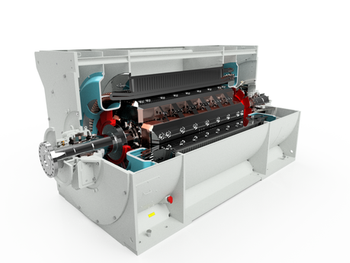

Under the additional contract for Train 5, Baker Hughes will deliver two Frame-7 gas turbines and six centrifugal compressors to support approximately 6 MTPA at the facility.

The Turbomachinery News Network, for the week of November 3, 2025, covers news from Yokogawa Electric, GE Vernova, Everllence, Concepts NREC, and Mitsubishi Heavy Industries.

The relocation of North American manufacturing is driving the industrial compression trend in the Asia-Pacific region, as more gas and air compressors are needed to support growth.

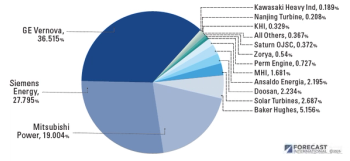

The loss of experienced personnel, underdeveloped manufacturing locations, and bottlenecked supply chains are posing significant challenges for building gas turbine capacity.

In addition to installing the world’s largest steam heat pump at Kendall Station, Everllence will include a dynamic process simulation and digital twin of the system.

MARA Holdings will construct numerous power generation facilities and data centers near MPLX’s natural gas processing plants across the Delaware Basin.

The new update improves volute modeling with enhanced 3D models and tongue geometries, in addition to expanded leakage path capabilities with a secondary network solver.

When using gear units within turbomachinery trains, operators should consider wear and degradation, torsional problems, lubrication, and more.

By 2030, the Jafurah gas field may produce up to 630,000 barrels of natural gas liquids and condensates, in addition to over 420 million cubic feet of ethane per day.

Anthony Brough and Christean Kapp of Dora Partners & Co. address their new partnership with Turbomachinery International and highlight the centrifugal and reciprocating compressor markets.

Under the pilot project, the partners will develop ammonia cracking systems to build out hydrogen and ammonia supply chains and decarbonization technologies.

The Turbomachinery News Network, for the week of October 27, 2025, covers news from GE Vernova, Baker Hughes, and Mitsubishi Power.

Since installation, the Fadhili Gas Plant has demonstrated a 10 – 15% reduction in amine and steam usage and an approximately 5% reduction in power usage.

Ever-increasing energy demands are placing a harsh spotlight on the supply chain and workforce challenges plaguing the turbomachinery industry.

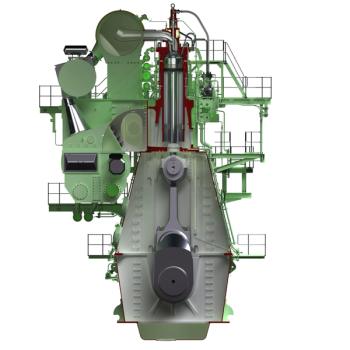

Under the meOHmare project, partners will develop a comprehensive concept for a CO2-neutral marine engine based on green methanol by year-end 2025.

Prior to the official methanol retrofit, Everllence invested in a dedicated 4S90 testbed engine which validated methanol performance under real operating conditions.

The Blue Point Number One Ammonia Project will produce blue ammonia via autothermal reforming while capturing up to 2.3 million metric tons of CO2 per year.

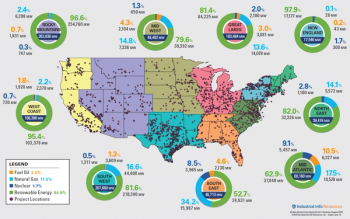

Roiled by executive orders, agency rulemakings, and other initiatives, the U.S. power generation landscape has shifted dramatically this year from renewables to dispatchable generation. What’s more, vast and ever-rising estimates of electric demand growth created by data centers, artificial intelligence, and advanced manufacturing are adding to the turbulence.

The plant’s post-combustion carbon-capture technology features exhaust gas recirculation, steam integration, and controls integration, reducing up to 90% of CO2 emissions.

The company’s coiled-tube drilling operations include its CoilTrak bottomhole assembly system and enhanced reservoir analysis driven by the GaffneyCline energy advisory.

The 2026 Handbook includes a comprehensive outlook of the U.S. power industry and gas turbine market, as well as an industry-wide directory and specifications listings.

The newly opened facility is expected to boost aeroderivative repair capabilities and reduce component lead times across Argentina, Brazil, Chile, and Uruguay.

The Turbomachinery News Network, for the week of October 20, 2025, covers news from NextDecade, Everllence, Doosan Enerbility, ExxonMobil, and Capstone Green Energy.

The new power plant will deploy Mitsubishi Power’s M701 JAC gas turbine with 30% hydrogen co-firing potential, helping to meet the Singaporean net-zero emissions target by 2050.

The LM6000 aeroderivative gas turbines, generating up to 112 MW for the Isaac Power Station, will allow QPM to expand the Moranbah gas production and infrastructure assets.

Xdot Bearing Technologies’ product offerings will accelerate growth in high-performance markets with advanced pumps, compressors, and high-speed rotating machines.

These 800-volt direct-current microturbines will be integrated in AI Power Blocks, which deliver power, liquid cooling, and computation in a rapidly deployable system.