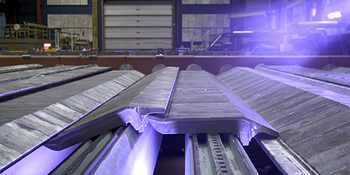

As part of the center’s equipment testing, development, and quality assurance work, liquid hydrogen pumps will be tested with hydrogen at -253°C.

As part of the center’s equipment testing, development, and quality assurance work, liquid hydrogen pumps will be tested with hydrogen at -253°C.

The company will provide 12 V32/44CR propulsion engines, six L32/44CR gensets, selective catalytic reduction for each engine, and three Alpha CP propellers.

CarbonEdge, leveraging an integrated dashboard, delivers real-time data and CO2 flow alerts across carbon capture, utilization, and storage (CCUS) infrastructure.

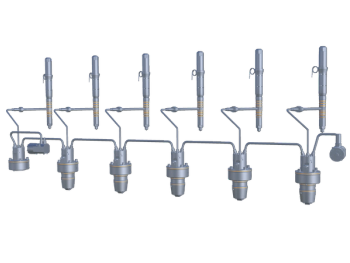

Initially installed on the MAN 49/60DF engine, the fuel-injection system comprises a uniform high-pressure pump, a newly developed injector, and the CR 1.6 valve group.

The mtu Series 1163 and 8000 engines are now equipped with exhaust gas aftertreatment, which reduces NOx emissions by 75% compared to the previous IMO II limits.

Earlier this year, GE Hitachi Nuclear Energy (GEH) received a £33.6 million Future Nuclear Enabling Fund grant from the U.K. Department for Energy Security and Net Zero.

Varme Energy’s proposed waste-to-energy facility will be located northeast of Edmonton, processing up to 200,000 tons of waste per year.

Sixteen gas engines will be installed across two power plants and an LNG terminal in East Malaysia and Indonesia.

ADNOC will acquire a 35% equity stake in the Baytown facility, which is slated to be the world’s largest, upon startup, low-carbon hydrogen and ammonia production plant.

The high-pressure centrifugal pump is hermetically sealed and designed with a magnetic coupling that aids torque transmission from the motor.

The company will study and deploy advanced drilling, completion, and production technologies during future development phases at the Tahiti and Jack/St. Malo facilities.

Systems with Intelligence (SWI) will integrate its fixed infrared sensors with GE Vernova’s DGA 900 Plus—an early-detection gas transformer monitoring system.

The ME-GI models are two-stroke propulsion engines operating on RoRo vessels, PCTCs, container vessels, bulk carriers, tankers, and LNG carriers.

The September/October 2024 issue highlights the dynamic shifts in the global LNG market that are affecting exports, production, capacity growth, and more.

In addition to Piñon’s two acid gas injection wells in the Delaware Basin, Enterprise will evaluate a third location to support up to 750 MMcf/d in total treating capacity.

Chevron will hold a 70% participating interest; Woodside Energy will hold a 30% stake; GS Caltex will potentially own a 5% interest upon regulatory approvals.

The industry recognizes two methods of decarbonization with gas turbines: low-carbon fuels and post-combustion carbon capture.

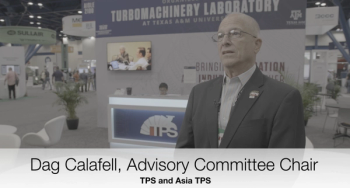

Dag Calafell of TPS talks plans for Asia TPS and the new wing of the Turbomachinery Lab at Texas A&M and its shift in focus from components to systems.

Anti-surge control systems prevent damage and improve turbomachinery performance by using controllers, valves, and transmitters to measure flow, pressure, and temperature.

At TPS 2024, Klaus Brun of Ebara Elliott addresses the company’s rebranding, prominent industry challenges, and upcoming products for sustainability and green energy.

Session speakers offer an analysis of gas turbines, including their working principles, thermodynamics, condition monitoring and maintenance, and bottom-cycle performance.

Fabio Zanetti de Souza of Compressor Controls Corp. shares how a compressor’s control system is a central contributor to increasing energy efficiency and reducing emissions.

A steam turbine’s control system should ensure stable operation throughout each phase: start-up, shutdown, and parallel operation.

Texas A&M’s TPS 2024 hosts a full house of rotating equipment engineers and technicians from more than 50 countries.

The Polish Ministry of National Defense will obtain a full engine depot and engine training capabilities, ensuring supply security for platforms using T700/CT7 engines.