During this episode, the Myth Busters break down the many terms associated with degradation, what components degrade, how it can be measured and minimized, and more.

During this episode, the Myth Busters break down the many terms associated with degradation, what components degrade, how it can be measured and minimized, and more.

During testing at the National Carbon Capture Center (NCCC), FrostCC successfully captured CO2 and co-pollutants from flue gas.

Test data from NASA’s Stennis Space Center informs the production configuration of the F130 engine’s Critical Design Review (CDR), scheduled for fall 2024.

A proper turbine-oil lifecycle management strategy ensures a varnish-free lubricating system.

The Turkish Naval Forces, as part of its MILGEM project, will install LM2500 engines on its Ada-, Barbaros-, and Gabya-class frigates and corvettes.

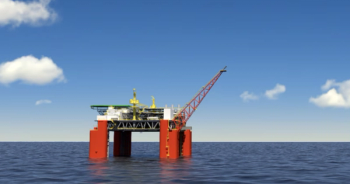

Existing platform and subsea equipment designs will drive cost efficiencies across the Kaskida hub’s construction, commissioning, and operations.

In addition to the dual-fuel methanol upgrade, the engines will achieve higher efficiency during diesel operation and feature control and safety systems.

Hydropower’s continued use as a renewable energy source requires complex hydro turbines and other rotating machines to electrify many regions worldwide.

In a series of recent aviation deals, Rolls-Royce agreed to deliver 14 Trent 7000 aircraft engines and signed TotalCare and SelectCare agreements with JSX and Vietjet.

NexGen Cryo’s pump and cold energy recovery turbine (CERT) technology serves the natural gas liquefaction, shipping, and regasification markets.

Rolls-Royce’s micro-reactor can meet the power requirements to enable long-term exploration and scientific efforts on the Moon and in space.

Testing will demonstrate the technology integration required for 100% hydrogen fuel operation on Rolls-Royce’s modified Pearl 15 engine.

Implementing phased array ultrasonic testing (PAUT) in turbine inspection and maintenance marks an evolution from traditional maintenance to more advanced solutions that ensure efficiency and reliability.

The facilities in Georgia and North Carolina will produce industrial gases, including liquid oxygen, liquid nitrogen, and liquid argon to supply growing regional markets.

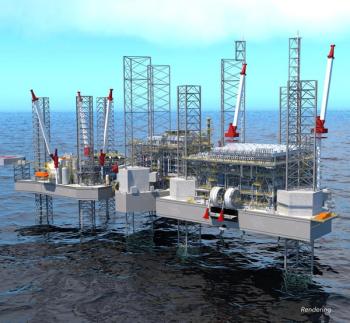

Fast LNG has a production capacity of 1.4 MTPA and will supply low-cost, clean LNG for New Fortress Energy’s downstream terminal customers.

Cryocap LQ technology is compact and uses a chemical-free, non-flammable process, enabling heat recovery and reuse to supply the district heating network.

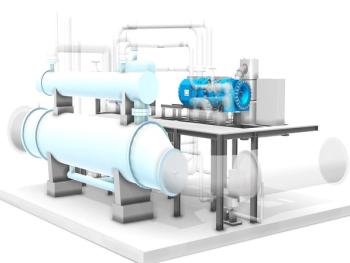

The Danish heat pump plant will use four oil-free, hermetically sealed HOFIM motor-compressor units without dry gas seal and lube oil systems.

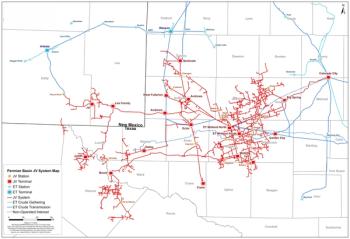

The Permian Basin joint venture will operate over 5,000 miles of crude oil and water gathering pipelines with crude oil storage capacity of more than 11 million barrels.

The company will support Wabash Valley Resources (WVR), an ammonia fertilizer producer, with turbomachinery and carbon sequestration solutions.

GE Vernova is delivering synchronous condensers and substations for energy security as more renewables are added to the grid.

The company’s water removal and carbon-capture system is suitable for mobile applications and can be retrofitted onto currently operating power plants.

The first installation of 100% hydrogen-powered mtu 4000 FNER/FV engines is planned for early 2025 at two combined-heat-and-power (CHP) plants for the Enerport II lighthouse project.

The ammonia-capable bulk carriers will be equipped with a dual-fueling mechanism comprised of a traditional diesel oil system and a clean-fuel system.

Upon completion, Ruwais LNG will consist of two 4.8 million tons per annum (mtpa) liquefaction trains for a total capacity of 9.6 mtpa.

This funding follows last year’s $11 million investment in the New York facility to support new capacity, facility maintenance, and equipment and tool management.