This year, the Western Turbine Users, Inc. (WTUI) conference took place virtually over the course of several weeks. This article summarizes week one.

This year, the Western Turbine Users, Inc. (WTUI) conference took place virtually over the course of several weeks. This article summarizes week one.

A study of major industrial firms by Senseye finds that large facilities lose 27 hours a month to machine failures on average at the cost of $532,000 for each hour of unplanned downtime.

New squeeze film damper bearings solve rotor stability problems

Global Compression Services has opened a new facility in Pennsylvania.

Many facilities operate steam turbines that are in need of modernization. Some units were installed 50 or 60 years ago with heat rates and reliability levels well below what current models can achieve.

5000 hours of corrosion protection in salt spray testing for metals

The German company is partnering to deploy artificial intelligence (AI) to aid decision-making in nitric acid plant operation.

MTU Power and Amazonas GT have signed a maintenance, repair, and overhaul agreement for five LM6000 turbines

Winterizing and protecting turbomachinery can mitigate the impact of extreme weather events on the industry’s ability to meet power demands.

Capstone Green Energy signed a 10-year service contract for two Capstone C1000S systems installed in Mexico

Reducing maintenance costs by upgrading aging inlet air-cooling systems.

The necessity of elevating the value of the customer experience and how growing trends like remote monitoring and digitalization can be used to achieve it.

Polymer achieves API 610 recognition for pump application in highly corrosive environments.

Technologies are emerging to perform maintenance, repairs, retrofits, and overhauls while gauging asset health remotely. Drones are being deployed for inspections. Some parts can be scarce, so plant operators are increasingly seeking alternatives.

Turbomachinery International has been a regular visitor to the Baker Hughes Annual Meeting (AM) in Florence, Italy. But this year, a virtual format had to suffice.

There are many reasons for turbomachinery problems and failures. Resonance, for example, is often overlooked.

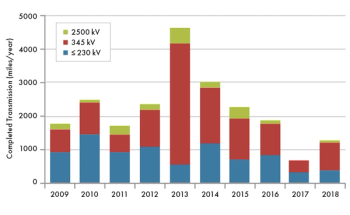

A stable renewable-rich grid needs transmission build-out, and incentivized ancillary services.

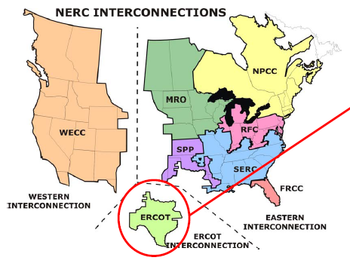

The ERCOT grid in Texas works well with renewable energy. But increasing the volume of renewables further may not be practical. More generation of all types and greater attention to winter readiness is needed.

The benefits of a digitalized, software-driven world for turbomachinery include the capacity to handle large amounts of data. Now, engineering teams can run larger, more complex simulations using cloud services and pass data seamlessly between teams.

How to cope with increasing cycling, start and ramp-up issues plaguing heat recovery steam generators.